In the modern world, corrugated board has become very popular as a material for the construction of garages. Such a garage is very easy to make, it takes a little time and minimal knowledge.

Build a garage like this for your car everyone can do it, without much effort. The metal profile is an inexpensive material, and it is much cheaper to build from it than from brick or concrete. Such a garage does not need a reinforced concrete floor, since a corrugated roof will protect well from precipitation.

This material is durable and can serve for about 40 years, if a special colored polymer coating is applied to a sheet of metal. For such a garage, you do not need to make an expensive frame, since the ribbing of the sheet makes it strong enough.

If you decide to make a garage yourself and use corrugated board for this, then you will need a little patience and skills in working with a screwdriver and a grinder. Almost all components of the garage are fastened with self-tapping screws. And the sheets are ordered in accordance with the required dimensions of the future garage.

Before construction you need to accurately calculate the required material and determine the sequence of work.

If there is a site plan, then it will greatly help in choosing a place for a garage. On the plan, it is necessary to mark all the buildings that are on the site, taking into account the fire safety and sanitary standards.

When choosing a place, you need to adhere to some rules:

It is important that the garage is of the correct size, which is also influenced by the size of the car. The standard of a regular garage, which many do, is 3/6 meter. But in the modern world, more and more large cars appear, and many families have several of them, so garages began to be made large.

It is important that the garage is of the correct size, which is also influenced by the size of the car. The standard of a regular garage, which many do, is 3/6 meter. But in the modern world, more and more large cars appear, and many families have several of them, so garages began to be made large.

For example , if you have one mini-vein, then a garage with a size of 4/7 meters and with a height of 3 meters will be enough for it.

In order to correctly calculate the size of the garage specifically for your car, you need to add the space that you need for the table and shelves, or some other items you need, to the size of the car. It has become popular in garages to make small rest rooms, which must also be taken into account.

Do not forget to add the width of the door to the dimensions of the car, so that it is convenient for you to open it, and you are not afraid to touch the wall or cabinet that is next to it.

Materials you need:

Of course, you can't do without a tool:

Of course, you can't do without a tool:

When the materials and tools are ready, you can begin preparatory work.

First you need to mark the area.

To do it, you need to hammer in the pegs or reinforcement, between which the rope is pulled.

In the middle of the marking along the perimeter, holes are dug in the corners, their size should be 0.5 meters / 0.5 meters, and also 0.5 meters deep.

When creating a drawing and building, you need to remember that insulating materials will take away part of the internal space.

For small mobile garages, it will be enough to draw up a drawing of the "box" itself.

Garage foundation done in a completely different way from home. Pipes need to be inserted into the prepared pits and concreted in the soil. After that, a trench with a depth of 30 centimeters is dug from pipe to pipe. If necessary, you can install formwork, after which everything is poured with concrete.

So that no cracks appear, it is recommended to reinforce the foundation and the floor. It is imperative to make the foundation higher than the floor in the garage.

So that no cracks appear, it is recommended to reinforce the foundation and the floor. It is imperative to make the foundation higher than the floor in the garage.

If you decide to make a viewing hole, it is necessary that the groundwater level is low. It is worth digging a hole right away, you can use an excavator, this will simplify and speed up the work process. In the pit, the walls are leveled and the edges are concreted, they can also be laid out with bricks. To make it more convenient, it is recommended to make steps or stairs so that you can go down into the pit without difficulty. Only after that the floor is concreted.

To make lighting in the pit, you need to lay the wiring before concreting the floor!

Next, it is worth weld to the pillars transverse and longitudinal fasteners, which are made of pipes or a corner. This requires welding, you can also use the services of a welder. The structure can be made combined, it can be metal and wood, then the fastening is done using bolts and self-tapping screws. The frame is made very simply - these are vertical as well as transverse posts.

Next, it is worth weld to the pillars transverse and longitudinal fasteners, which are made of pipes or a corner. This requires welding, you can also use the services of a welder. The structure can be made combined, it can be metal and wood, then the fastening is done using bolts and self-tapping screws. The frame is made very simply - these are vertical as well as transverse posts.

When the garage frame is ready, you can do the formwork. To do this, sand is poured 5 centimeters, then crushed stone, everything from above is filled with cement, this will be the floor for the garage. The floor is laid out with paving slabs, or simply covered with rubble, if you wish, you can leave the floor from the ground.

The frame for the walls must have a step about 45 centimeters, but no more. So that the gate can reliably hold onto the frame, it is worth weld the crossbeams across, after which they are connected to the corner pipes of the frame. If the frame itself is made efficiently and symmetrically, then sewing on the sheets will be quite simple.

When the foundation is poured and the formwork is made, it is better to wait a week for the structure to dry. Only then can you start working with the walls.

The frame structure can also be welded, with the necessary equipment and welding skills.

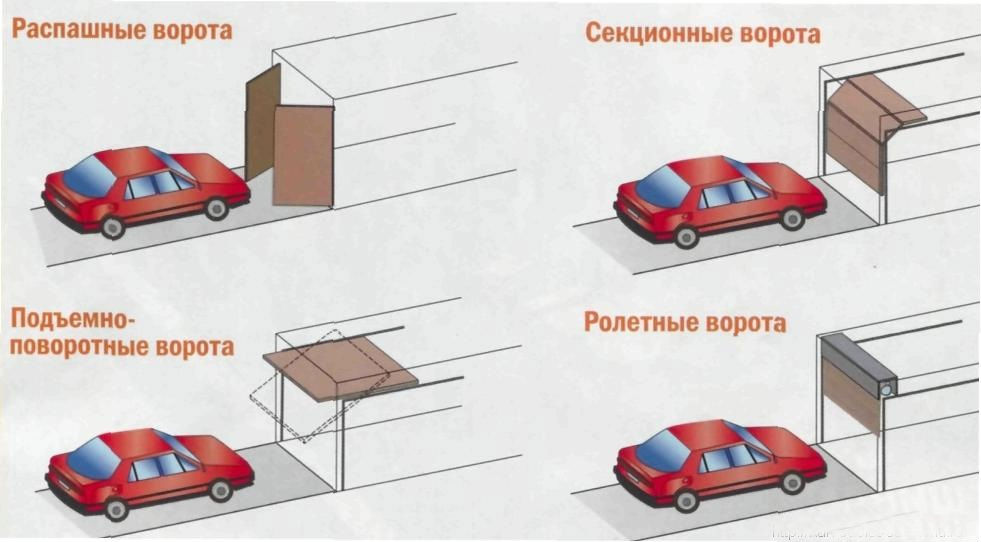

Make good Gates it is also possible from a metal profile, their width, ideally, should be the same as the front wall.

To make a shed roof from a metal profile, the sheets are attached parallel to the waves on the walls. With this installation, the water will be able to drain well and will not linger. In this case, the metal profile should protrude from the walls by 2 - 3 centimeters.

The sheets are securely attached, while the overlap in one wave is also observed. The joints must be treated with a bituminous sealant.

In order for the garage to be comfortable and warm, it must be insulated from the inside.... This will provide a temperature rise of at least 5 degrees. For this purpose, roll and sheet heaters are used.

In order for the garage to be comfortable and warm, it must be insulated from the inside.... This will provide a temperature rise of at least 5 degrees. For this purpose, roll and sheet heaters are used.

For insulation, a thermal insulation film is attached to the walls, which will protect against heat loss and condensation. Next, foam or any other polystyrene foam is glued using a special glue, while the joints will need to be foamed. The gate itself is insulated using the same method.

If you decide to use roll insulation, then you need to make an additional frame... Wooden crossbars are nailed to the main frame with a distance of 60 centimeters. And only then the insulation itself is laid under them, which would also be better glued.

Very often, motorists spend a lot of time in the garage. Therefore, it is important to make the garage in the middle cozy and bright.

Very often, motorists spend a lot of time in the garage. Therefore, it is important to make the garage in the middle cozy and bright.

Today there is a wide variety of building materials, which makes it possible to translate any idea into reality.

First you need to make the walls strong, because they will have all kinds of cabinets and shelves.

To make a high-quality finish of the garage with your own hands, you need to choose the right material and do everything exactly according to the technology.

Materials that will be purchased for decoration must be safe and fire resistant... Also keep in mind that there will be a lot of chemicals in the garage, so the material should not absorb unnecessary odors, and it should be practical.

Blue tones and geometric shapes are very suitable for the garage, the transition of colors from dark to light also looks good.

Garage decoration is divided into several stages:

When all the electrical work is done, you need to treat the ceiling with a soil composition. After applying the primer, the ceiling can be plastered or sheathed with plastic, all at your discretion.

It is not so difficult to make a garage from a metal profile, the main thing is to choose high-quality material and carry out all the work clearly in order. You will not need so much money investment than building a brick garage, and the result can be no worse, because a well-made garage can last about 40 years.